Control Panels

Control panels and boards are the main part of any modern production process. They provide control, monitoring and efficient dispatching of facilities at power enterprises and across other industrial sectors.

Radiy offers a wide range of innovative solutions for controlling production processes, including:

- Control panels for power plants and substations;

- Control panels for infrastructure facilities;

- Control panels for test benches;

- Training models of control panels.

Everything depends on the customer’s requirements and the set of functions needed for a particular project. The development of such equipment is carried out in accordance with the regulatory documents governing industrial-purpose products and the applicable safety standards.

Where are control panels used?

Mechanical engineering

and metal processing

Industrial

automation

Construction

equipment

Transport

and logistics

Shipbuilding

and marine transport

Chemical

and pharmaceutical industries

Energy

facilities

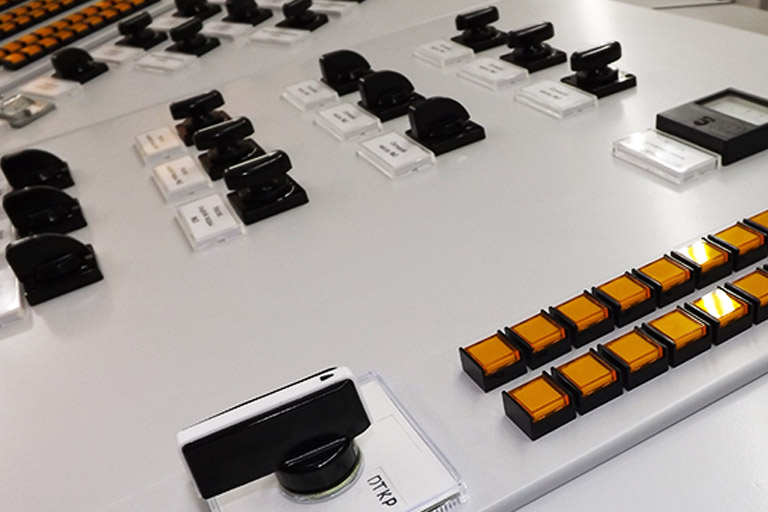

Industrial control panels are specialized devices or consoles used to operate equipment, machines, and control production processes at industrial facilities.

Their designs may include measuring and recording instruments, control elements, signaling devices, mimic diagrams, components integrated into process control systems, and more.

A control board is typically made of vertical panels, while a control console consists of inclined panels that provide convenient access to process control elements.

Types of control panels

The following types of control panels are distinguished:

- Main Control Panel (Main Control Room);

- Emergency Control Panel (Emergency Control Room);

- Local Control Panel;

- Common-Plants Control Panels and more.

Automation consoles for the power industry: Main Control Room

Main Control Room is the main control center of a nuclear power unit, which ensures uninterrupted control over its operation. Thanks to Main Control Room, the operator has full access to information about the state of systems and ability to respond quickly to any changes.

A modern MCR includes:

- Information panels that display key data: unit mimic diagrams, technological parameters, alarm signals.

- A control console equipped with the main control elements to ensure quick interaction with the systems.

- Operator workstations — ergonomic consoles designed to enhance personnel comfort and work efficiency.

Operator Consoles: Advantages from Radiy for Process Control Systems (PCS)

Choosing a Ukrainian manufacturer of control consoles is a smart strategic decision because it offers:

- Support for a national manufacturer and the economy

- Direct communication with the producer Customized turnkey solutions

- Competitive pricing without compromising quality

- Competitive pricing without compromising quality

- Fast maintenance and technical support

- Compliance with Ukrainian and international standards

- Warranty and service

Development and Implementation Stages

The development and implementation of control consoles for industrial process control systems is a complex, multi-stage process that involves both engineering and software solutions. The main stages include:

- Needs analysis and technical specifications

- Console design

- Programming of controllers and HMI for control systems

- Manufacturing and installation

- Connection to the system

- Pre-commissioning

- Personnel training and commissioning Support, maintenance, and updates

This approach ensures compliance with the highest-level requirements and guarantees maximum reliability, safety, and efficiency of the console’s operation.

Projects implemented by Radiy

The company's portfolio is quite extensive. This equipment and its elements, in various configurations, are part of such I&C systems as the Group and Individual Control System and the Automatic Regulation, Power Control, Unloading, Limitation, and Accelerated Preliminary Reactor Protection System.

Control consoles and their components developed by Radiy, supplied in various configurations, have been installed at all nuclear power plants in Ukraine. In particular, in 2016, two nuclear island I&C systems with common plant control panels were manufactured. And in 2017, a project to supply a large control console for the same NPP was completed.

Control consoles are widely used as a part of the Safety Control Systems (SCS) of nuclear power plants. Between 2005 and 2024, 28 ESFAS units were supplied to nuclear power plants in Ukraine and Bulgaria.

European projects

In 2025, the hardware modernization of the Reactor Trip System, Automatic Power Regulation and Discharge, and Limited Power equipment for Units 6 and 5 of Kozloduy NPP, Bulgaria, was completed. Our control panels are included in the list of equipment required for this modernization.

No automated process control system, nor any system ensuring maximum operator comfort and safety, can function without control consoles, control panels, or their components.